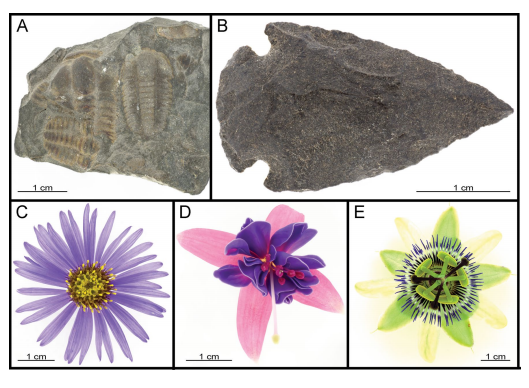

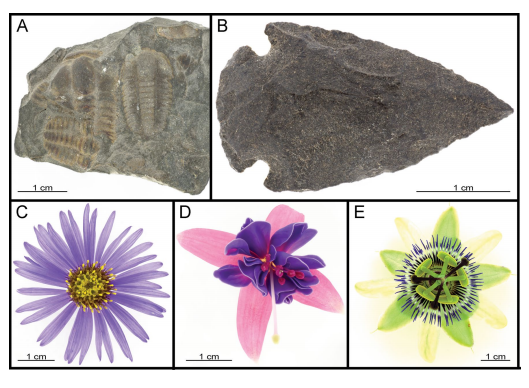

Exemplifying the wide-ranging versatility of 3D printing, researchers have integrated the technology for accompanying scientific photography, detailing their recent study in “Illuminating nature’s beauty: modular, scalable and low-cost LED dome illumination system using 3D printing technology.”

Research may be vital to scientific advancement, but without a suitable presentation, it could mean very little to anyone. This begins with excellence in photography but also relies heavily on lighting. Currently, dome-style illumination systems are most commonly preferred by scientists showing their work—whether in taxonomy, morphology, systematics, natural history collections, or more. There are drawbacks though, due to lack of affordability and ease in use, leading the authors to explore 3D printing for a less expensive, modular LED dome design with the following features:

- Sliding table for arranging objects inside the dome

- Optional iris diaphragm for improved lighting source

- Battery for use in the field

Samples were 3D printed on the Prusa i3 MK3S using PLA. After discarding and re-working several iterations for the dome, the authors added an LED strip for lighting that was flexible, adhesive, and fitted to the baseplate. Much less assembly was required, and “little to no” soldering was necessary. Ultimately, one SMD LED ring (40 mm diameter) was used for lighting, powered by a DC coaxial connector:

“We tried to design our own LED setup to assemble as many LED’s as possible in the small sized dome, by connecting single SMD LED’s with enameled copper wire and the needed resistors. However, this procedure is not beneficial and too time consuming,” explained the authors.

In comparison to similar lighting created in recent, previous research, this technique for creating a 3D printed dome provides the necessary affordability, accessibility, and reproducibility. The researchers expect it to be helpful for students and labs, and especially when there is an emphasis on budget.

FDM 3D printing is recommended, with printer settings provided by the researchers; however, users engaged in 3D printing these parts may need to adjust the temperature for the printer bed or extruder, as well as experimenting with settings for the extrusion multiplier to control the amount of filament used. Layer thickness must be taken into consideration too: while higher thickness means decreased resolution, 3D printing is faster. Lower layer thickness means better resolution but more time in production.

“If no 3D-printer is at hand, there are many local or online 3D-printing services, that can be commissioned, to print our provided models from a wide range of materials and in customized sizes,” stated the authors.

[Source / Images: “Illuminating nature’s beauty: modular, scalable and low-cost LED dome illumination system using 3D printing technology”]

If you're in need of 3D interior and exterior design services in the USA, our platform offers a comprehensive solution to bring your architectural projects to life. Through our service, you can request detailed 3D renderings that showcase both the interior and exterior of your property. Whether you're designing a home, office, or commercial space, our experts deliver photorealistic visualizations that highlight every element, from furniture arrangements to building facades, ensuring that your vision is accurately represented.

Through our website, you can easily access 3D interior and exterior design services tailored to your specific needs. With our help, you'll be able to create stunning visual representations of your designs, allowing you to present them to clients, investors, or stakeholders in a professional and engaging manner. Our team focuses on bringing out the best in your designs, ensuring that both the interior spaces and exterior elements are rendered with the highest level of detail and realism.