As implants continue to be a challenge for dental patients, researchers from Taiwan are experimenting with better ways to accommodate bone defects after failed implants must be removed. Results of their study are outlined in ‘3D laser-printed porous Ti6Al4V dental implants for compromised bone support.’

Lack of suitable and supporting alveolar bone is a common issue for dental patients with failed implants, and especially those who have developed inflammation with peri-implantitis. Defects may cause less attachment and bone regeneration, along with decreased clinical improvement. With bone tissue engineering via bioprinting (here, Bio-ActiveITRIdental implants were fabricated on the EOSINT M 280 system) the authors foresee a range of new possibilities for patients through the ability to create tissue scaffolds with features like:

- Internal architecture

- Porosity

- Interconnectivity

- Patient-specific dimensions

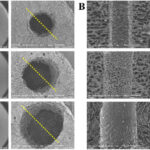

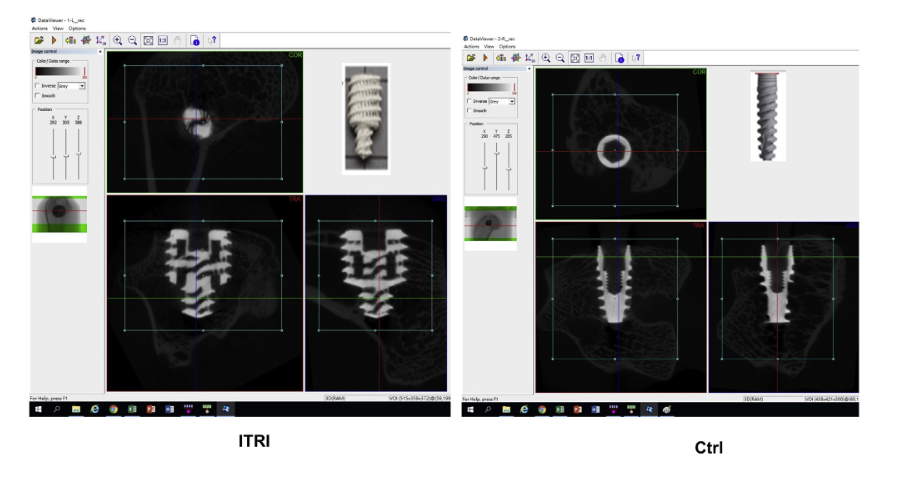

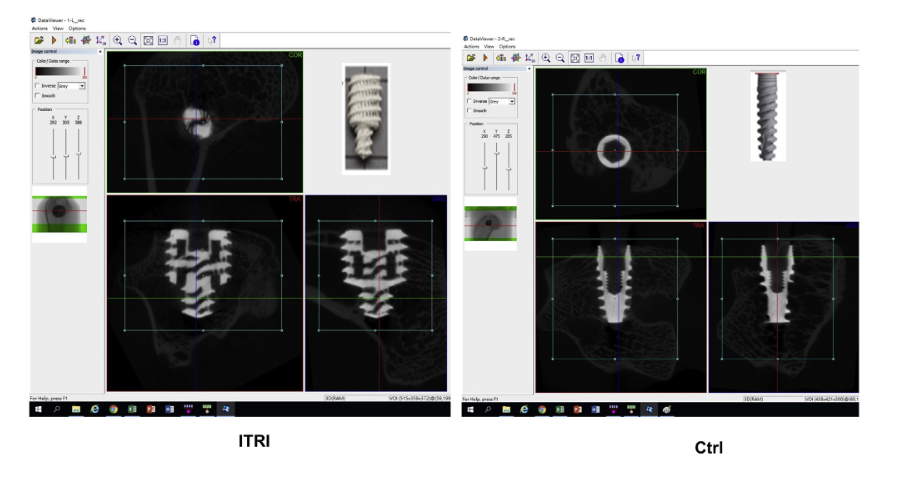

Implants were tested on rabbits, with the specimens available both for X-ray and CT assessment, along with biomechanical analysis. Bone ingrowth was tested at different implant locations, with each area evaluated. Biomechanical testing exhibited the effect the histologic responses on implants, along with ‘progressive increase’ in strength as related to bone growth, along with mineralization and maturation of the engineered tissue. Implants with a rougher surface tended to show better osseointegration, compared to the control group samples with smoother surfaces.

Stiffness occurred because of the powder sintering technique—also responsible for creating a network of porous structures. Both compression and fatigue tests also demonstrated suitable properties, allowing the research team to compromise between mechanical properties and pore interconnectivity. By enlarging pore width at the nanoscale, the authors were also able to increase bioactivity features as well as accelerating osseogenesis. Surface roughness remained the same.

“Although fabricating Ti alloy dental implants with defined porous scaffold structure is a promising strategy for improving the osseoinduction of implants, in a study using laser beam melting 3D printing technique to fabricate porous Ti6Al4V dental implant with three controlled pore sizes (200, 350 and 500mm), the 350 and500mm pore-sized implants demonstrate a better biocompatibility in terms of cell growth, migration and adhesion,” concluded the researchers. “The pore size of 350mm provides an optimal provides an optimal potential for improving the mechanical shielding to the surrounding bones and osseoinduction of the implant itself.

“Further study on the effect of different pore size and porosity without sacrificing their mechanical property is mandatory to optimize the clinical outcome.”

Bone regeneration continues to be a source of challenge for medical researchers, spanning numerous areas of medicine. In 3D printing the hope is that with patient-specific cells, better sustainability is possible. And while dental implants are important for so many patients today, a wide range of 3D printed implants have been created for the sustainability of bone, from the use of nanofibers with tubes to porous metallic biomaterials, and even titanium alloys.

What do you think of this news? Let us know your thoughts! Join the discussion of this and other 3D printing topics at 3DPrintBoard.com.

[Source / Images: ‘3D laser-printed porous Ti6Al4V dental implants for compromised bone support’]

If you're in need of 3D interior and exterior design services in the USA, our platform offers a comprehensive solution to bring your architectural projects to life. Through our service, you can request detailed 3D renderings that showcase both the interior and exterior of your property. Whether you're designing a home, office, or commercial space, our experts deliver photorealistic visualizations that highlight every element, from furniture arrangements to building facades, ensuring that your vision is accurately represented.

Through our website, you can easily access 3D interior and exterior design services tailored to your specific needs. With our help, you'll be able to create stunning visual representations of your designs, allowing you to present them to clients, investors, or stakeholders in a professional and engaging manner. Our team focuses on bringing out the best in your designs, ensuring that both the interior spaces and exterior elements are rendered with the highest level of detail and realism.