In the recently published ‘Effects of Printing Parameters on the Fit of Implant-Supported 3D Printing Resin Prosthetics,” authors Gang-Seok Park, Seong-Kyun Kim, Seong-Joo Heo, Jai-Young Koak, and Deog-Gyu Seo delve into a niche realm in 3D printing: dental prosthetics. These types of implants can be challenging in many cases, but new technology brings enormous potential to the dental field.

The authors investigated 3D printing parameters on both fit and internal gap issues in dental prosthetics fabricated with resin, fabricating samples to examine fit. In dental manufacturing, additive manufacturing processes offer the advantages of speed in manufacturing, less waste in use of materials like resin, as well as being quieter and putting out less heat in the end. Digital light processing is commonly used in dentistry, with a digital mirror device (DMD).

Previous research has been performed regarding the fit of such dental implants, but none so far regarding fit in connection with parameters like orientation and thickness. There are numerous ways to measure gaps, both marginal and internal, to include:

- Direct view technique

- Cross-sectioning technique

- Impression replica technique

- Optical coherence tomography

- Micro-computed tomography

A model was 3D printed for two implants with customized abutments for the mandibular second premolar and second molar area.

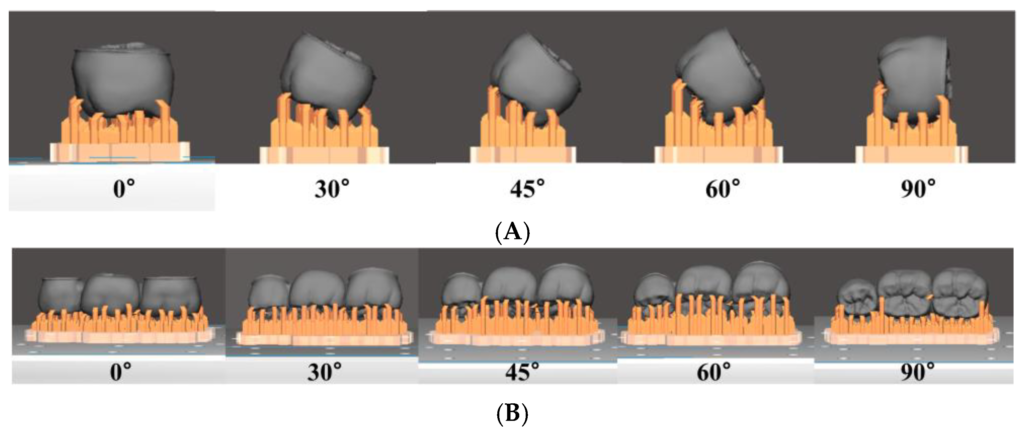

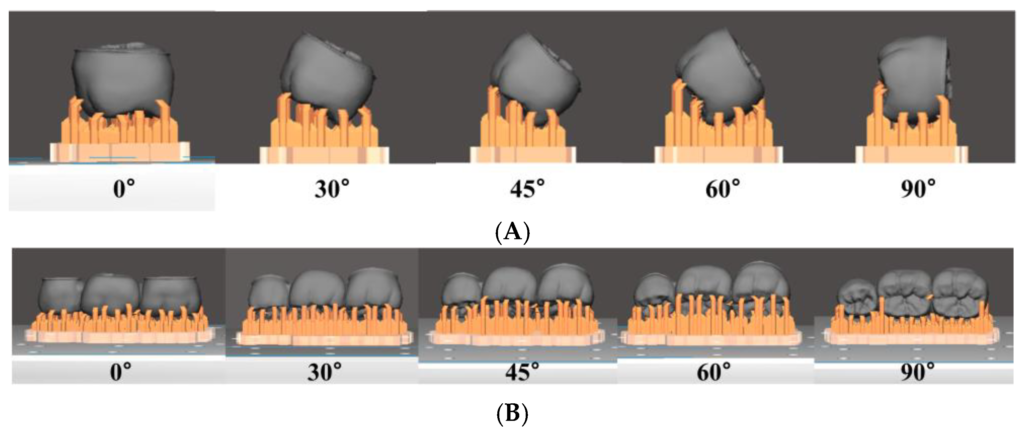

The researchers used a D2-120 DLP 3D printer, with five build orientations: 0°, 30°, 45°, 60° and 90°, and two-layer thicknesses of 50 µm and 100 µm.

“In the 0° build orientation, supporting structure was connected perpendicular to the occlusal surface of the prosthesis,” stated the authors. “In the 90° build orientation, supporting structure was connected perpendicular to the lingual surface of the prosthesis.”

In all, 100 samples were printed, along with ten milling prosthetics. They were all examined under a microscope for defects, with no adjustments made.

“At the 50 µm layer thickness, the 60° build orientation was the smallest followed by the 45° build orientation and at the 100 µm layer thickness, 90° build orientation was significantly smaller than the other build orientations,” stated the authors. “At 45° and 60° build orientations, the 50 µm layer thickness group was significantly smaller than the 100 µm layer thickness group, and at 90° build orientation, the 100 µm layer thickness group was significantly smaller than the 50 µm layer thickness group.”

The researchers theorized that the large cervical/axial gap was caused by the sizeable cement space. In noting that they also found variances for marginal fit and internal gap, the researchers realized several issues could be to blame: support structure connections, errors due to no support, the appearance of layer output due to 3D printer changes.

“Considering the marginal fit and the internal gap together, build orientation of 45° and 60° would be recommended. The marginal fit of 3D printed prosthesis with the 100 µm layer thickness was like that of the 50 µm layer thickness,” concluded the researchers. “When the prosthesis is manufactured by 3D printing with favorable parameters, it is possible to obtain a comparable fit to the prosthesis manufactured by the milling. The marginal fit of 3D printing and milling prostheses was within the clinically acceptable limit for marginal fit of conventional cast restoration.”

While 3D printing is making huge impacts in the dental field, a variety of prosthetics are being fabricated today—and making a huge difference in the lives of so many individuals, from soft tissue maxillofacial prosthetics to ocular prosthetics and a wide range of developments and choices for children. What do you think of this news? Let us know your thoughts! Join the discussion of this and other 3D printing topics at 3DPrintBoard.com.

[Source / Images: ‘Effects of Printing Parameters on the Fit of Implant-Supported 3D Printing Resin Prosthetics’]

If you're in need of 3D interior and exterior design services in the USA, our platform offers a comprehensive solution to bring your architectural projects to life. Through our service, you can request detailed 3D renderings that showcase both the interior and exterior of your property. Whether you're designing a home, office, or commercial space, our experts deliver photorealistic visualizations that highlight every element, from furniture arrangements to building facades, ensuring that your vision is accurately represented.

Through our website, you can easily access 3D interior and exterior design services tailored to your specific needs. With our help, you'll be able to create stunning visual representations of your designs, allowing you to present them to clients, investors, or stakeholders in a professional and engaging manner. Our team focuses on bringing out the best in your designs, ensuring that both the interior spaces and exterior elements are rendered with the highest level of detail and realism.