While the realm of bioprinting has continued to expand significantly in the past few years, allowing for better sustainability of cells in the lab—and the bioink used to print them—the end goal is almost always to get just that much closer to 3D printing organs, meaning the potential for enormous change in the current medical culture of patients suffering and often dying while waiting for transplants. Now, with a collaboration between startup FluidForm and Carnegie Mellon University, scientists may actually be much closer than ever to bioprinting a human heart.

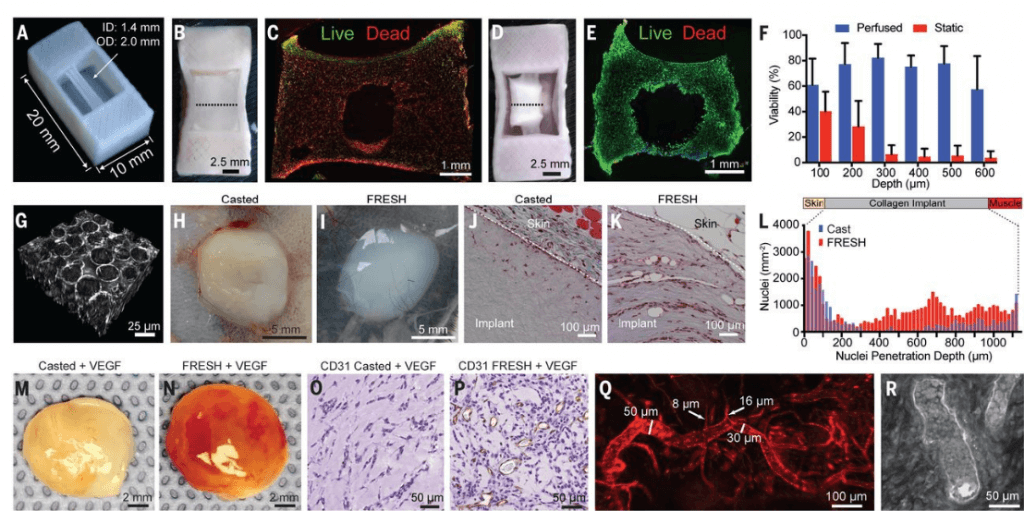

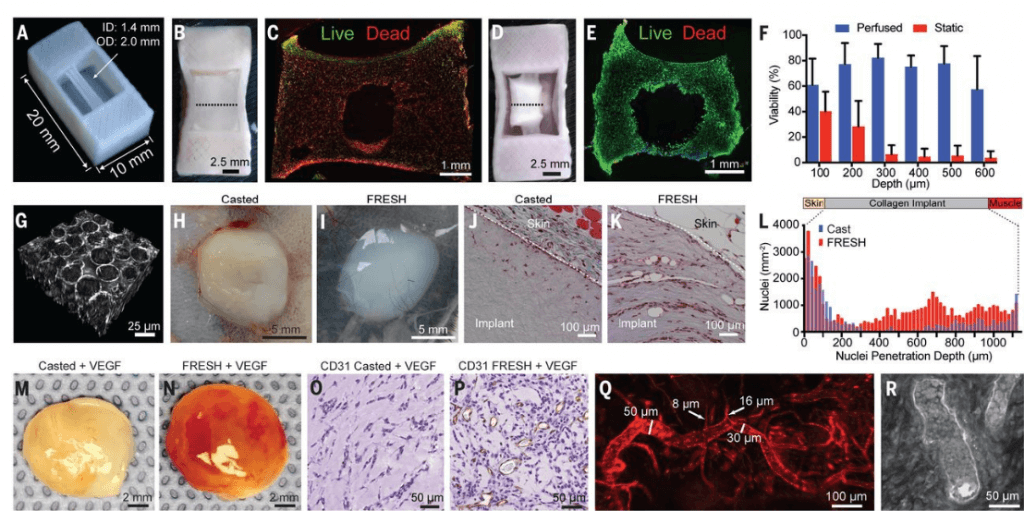

Findings on the subject were published recently in the August 2nd edition of Science regarding work by the Carnegie Mellon University research team, made up of co-first authors and FluidForm co-founders Andrew Lee and Andrew Hudson, and the nine members of the Carnegie Mellon team. They have just developed an advanced version of Freeform Reversible Embedding of Suspended Hydrogels (FRESH) technology which allows them to 3D print collagen. With these new advancements, the scientists can fabricate cardiac components, including tiny blood vessels, valves, and beating ventricles.

The patent for this important work belongs to FluidForm, headquartered in both Pittsburgh and Boston.

“We now have the ability to build constructs that recapitulate key structural, mechanical, and biological properties of native tissues,” said Prof. Adam Feinberg, CTO and co-founder, FluidForm, and Principal Investigator, Regenerative Biomaterials and Therapeutics Group, Carnegie Mellon, where the research was done. “There are still many challenges to overcome to get us to bioengineered 3D organs, but this research represents a major step forward.”

Created from MRI data, the FRESH bioprinted hearts were comprised of small cardiac ventricles printed with human cardiomyocytes that demonstrated the following:

- Synchronized contractions

- Directional action potential propagation

- Wall-thickening up to 14 percent during peak systole

“We found that FRESH 3D-bioprinted hearts accurately reproduce patient-specific anatomical structure as determined by micro–computed tomography. Cardiac ventricles printed with human cardiomyocytes showed synchronized contractions, directional action potential propagation, and wall thickening up to 14% during peak systole,” state the researchers in their paper, “3D bioprinting of collagen to rebuild components of the human heart.”

Other obstacles are still present though, as scientists wrestle with generating the billions of cells needed for 3D printing larger tissues.

“Although the 3D bioprinting of a fully functional organ is yet to be achieved, we now have the ability to build constructs that start to recapitulate the structural, mechanical, and biological properties of native tissues,” stated the researchers in their paper.

While previously scientists have projected bioprinting of organs in the very near future, it has proven to be much more difficult than anticipated, obviously. Milestones continue to be surpassed, but challenges continue to erupt—mainly in keeping cells alive in coordination with the proper technology—meaning materials, software, and hardware continue to be a significant focus. With FRESH, a temporary support gel is used to 3D print collagen scaffolds, driven by a rapid pH change that drives collagen self-assembly. There is promise not only for 3D printing hearts, however, but a range of different tissues and organs in the future.

“FluidForm is extraordinarily proud of the research done in the Feinberg lab” said Mike Graffeo, CEO, FluidForm. “The FRESH technique developed at Carnegie Mellon University enables bioprinting researchers to achieve unprecedented structure, resolution, and fidelity, which will enable a quantum leap forward in the field. We are very excited to be making this technology available to researchers everywhere.”

FluidForm is unveiling its first product, LifeSupport™ bioprinting support gel, commercializing FRESH technology and giving scientists and researchers everywhere the opportunity to 3D print collagen, cells, and biomaterials.

3D printing has been used to help a wide range of patients with heart issues, from cardiac patches to cardiac phantoms, catheter devices, and more. What do you think of this news? Let us know your thoughts! Join the discussion of this and other 3D printing topics at 3DPrintBoard.com.

[Source / Images: FluidForm press release]

If you're in need of 3D interior and exterior design services in the USA, our platform offers a comprehensive solution to bring your architectural projects to life. Through our service, you can request detailed 3D renderings that showcase both the interior and exterior of your property. Whether you're designing a home, office, or commercial space, our experts deliver photorealistic visualizations that highlight every element, from furniture arrangements to building facades, ensuring that your vision is accurately represented.

Through our website, you can easily access 3D interior and exterior design services tailored to your specific needs. With our help, you'll be able to create stunning visual representations of your designs, allowing you to present them to clients, investors, or stakeholders in a professional and engaging manner. Our team focuses on bringing out the best in your designs, ensuring that both the interior spaces and exterior elements are rendered with the highest level of detail and realism.