A research team from the Peking University People’s Hospital and Key Laboratory for Musculoskeletal Tumor of Beijing has successfully demonstrated the feasibility of 3D printing technology in pelvic endoprostheses.

By definition, an endoprosthesis is an artificial hip joint designed and developed to replace the functions of an actual hip joint. Surgeons often utilize endoprostheses for patients suffering from pelvic tumors who require pelvic reconstruction to recover the functions of their hip joints.

Prior to the introduction of 3D printing technology in the medical industry, endoprostheses were manufactured by demand using conventional methods and technologies. The substantially higher level of precision and accuracy required in the development of customized endoprostheses made the device incredibly expensive for patients.

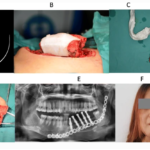

On February 1, the team of researchers at the Peking University People’s Hospital and Key Laboratory released a report based on an extensive study conducted on the viability and applicability of 3D printing technology in the process of implanting and manufacturing pelvic endoprostheses. The team utilized a 3D printer to create the implants with sophisticated 3D scanning and designing software.

Throughout a two-year period between September of 2013 and December of 2015, 35 patients at the Peking University People’s Hospital underwent a complete pelvic reconstruction. The pelvic implants were solely created using enterprise-grade 3D printers, for maximum precision and efficiency.

Upon the completion of the 3D printed pelvic endoprosthesis implants, 25 patients survived without major complications or evidence of disease, five patients survived with disease and five died due to metastatic disease.

The five deaths recorded during the two-year study do not represent weaknesses or impracticality of 3D printing technology in developing endoprostheses. According to the Canadian Cancer Society (CCS), patients suffering from renal pelvis and ureter cancers or tumors only have around 10 to 20 percent survival rate.

Although the survival rate of pelvic tumor patients varies depending on the stage and grade, patients with cancer in the grades of 1 to 3 have a 80 percent survival rate while patients with high grade and localized cancer have around 5 to 30 percent survival rate.

According to the study, more than 13 high grade cancer–grade 4 localized cancer–patients underwent the 3D printing-based pelvic reconstruction process and out of those 13 patients, 5 passed away in the midst of recovery. More importantly, the research team noted that none of the patients had a deep infection due to the accuracy and precision of 3D printing technology.

“Complications included seven patients with delayed wound healing and two with a dislocation of the hip. None had a deep infection. For the 30 surviving patients, the mean Musculoskeletal Society 93 score was 22.7 (20 to 25) for patients with an iliac prosthesis, 19.8 (15 to 26) for those with a standard prosthesis, and 17.7 (9 to 25) for those with a screw-rod connected prosthesis,” the study states.

Particularly, the research team discovered that 3D printing technology is viable and practical in precisely matching implants and the host bone. Since surgeons can obtain a detailed 3D scan of the host bone and derive endoprostheses with 3D printers, researchers explained that implants adapt better to the host bone, without any severe complications and diseases. You can access the study here. Discuss in the Pelvic Implants forum at 3DPB.com.

If you're in need of 3D interior and exterior design services in the USA, our platform offers a comprehensive solution to bring your architectural projects to life. Through our service, you can request detailed 3D renderings that showcase both the interior and exterior of your property. Whether you're designing a home, office, or commercial space, our experts deliver photorealistic visualizations that highlight every element, from furniture arrangements to building facades, ensuring that your vision is accurately represented.

Through our website, you can easily access 3D interior and exterior design services tailored to your specific needs. With our help, you'll be able to create stunning visual representations of your designs, allowing you to present them to clients, investors, or stakeholders in a professional and engaging manner. Our team focuses on bringing out the best in your designs, ensuring that both the interior spaces and exterior elements are rendered with the highest level of detail and realism.