‘3D printed rotating spinnerets create membranes with a twist,’ authored by Tobias Luelf, Deniz Rall, Tim Femmer, Christian Bremer, and Matthias Wessling, explores how progressive technology can be used to create new architectures with membranes, helpful in critical applications like separating gas, filtration exercises, and blood dialysis for medical patients. With their new technique and methodology, the authors hope to customize designs for spinnerets to improve the process of using membrane materials.

In explaining current changes found in processes using membranes, the authors mention that for filtration processes today, there have been obstacles in transfer from the surface of the membrane, along with the overall performance of the process. There are numerous ways to control both polarization and fouling, but the authors focus on directing secondary flows back into the feed channel, eliminating the chance for issues, also noting the desirability of designing a spinneret tailor-made for such processes, resulting in suitable geometry. They also work to improve on other problems in mass transport resistance by experimenting with fiber membrane geometries.

Both flat sheet and hollow fiber membranes were used in the study, but the authors point out that in the use of flat sheet membranes, most researchers have used both ‘spiral-wound and stagged flat modules,’ with spacers in the channels, not only serving as ‘mixing devices’ but also controlling the height. In comparison, hollow fiber membranes do not have an access channel, and inserting mixing elements is not possible in smaller shapes. In 3D printing a spinneret, the authors foresee potential due to the classic benefits of 3D printing so many other desktop users, small businesses, research labs, and large companies and manufacturers have taken advantage of, from savings on the bottom line in the budget whether it is a research study or a new part design for a corporation, to efficiency in production, self-sustainability in planning and production, and more:

“It would be highly desirable to become independent of current spinneret manufacturing processes and move towards quick, cheap and flexible design methods enabled by 3D printing,” state the researchers.

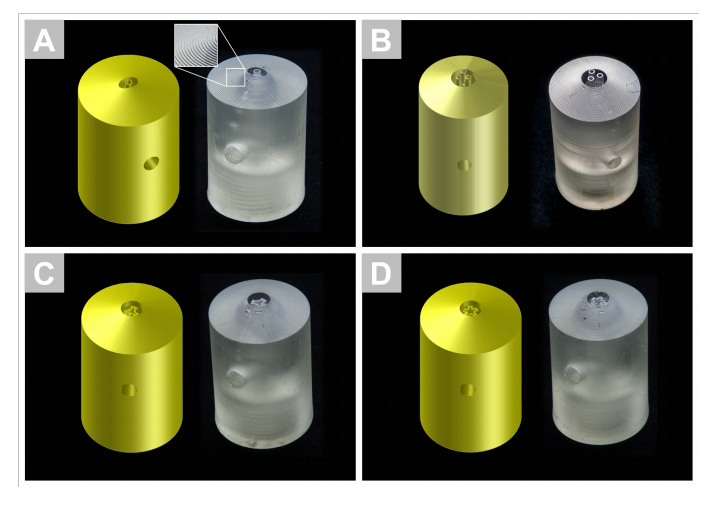

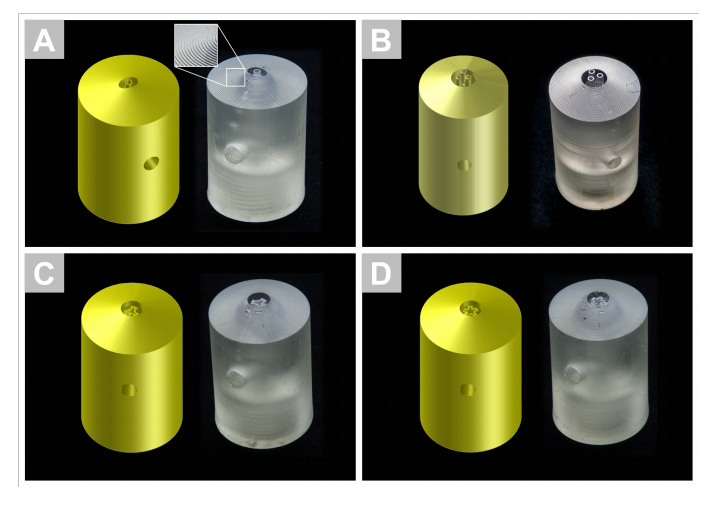

The spinnerets they created offer improvement due to the freedom in design, mainly in the cross-section of the hollow fibers. The team was able to spin polymeric fibers with mixing potential and ‘no limitation’ in terms of packing density—and noted that it was necessary to create two new parameters: spinneret geometry and rotational speed of spinneret, with most of them fabricated via stereolithography. The researchers continued to emphasize the benefits offered by the ‘higher degree of freedom,’ in comparison to traditional techniques, as the bore fluid needle is connected to the body at one quarter, with most of the spinneret left to disperse the polymer.

“The produced multibore fibers have a stable 3D geometry with separated lumen channels. In addition, we take the concept of spinneret design to another level by combining the typically implemented co-extrusion with the design of a rotation assembly,” concluded the researchers. “The resulting fibers combine a multibore approach with high packing density with a fiber lumen rotation enabling dean vortice formation during operation.

“With this approach we are able to fabricate fibers with rotating inner or outer geometries. Thus, on the basis of our research one is able to tailor both the membrane inner and outer mixing properties to a separation task.”

As the range of materials available continues to expand in 3D printing, researchers experiment with many types of different fibers such as those embedded for electronics to continuous fibers to nanotubes and nanocellulose. Find out more about hollow fiber membranes being 3D printed here. What do you think of this news? Let us know your thoughts! Join the discussion of this and other 3D printing topics at 3DPrintBoard.com.

[Source / Images: ‘3D printed rotating spinnerets create membranes with a twist]

If you're in need of 3D interior and exterior design services in the USA, our platform offers a comprehensive solution to bring your architectural projects to life. Through our service, you can request detailed 3D renderings that showcase both the interior and exterior of your property. Whether you're designing a home, office, or commercial space, our experts deliver photorealistic visualizations that highlight every element, from furniture arrangements to building facades, ensuring that your vision is accurately represented.

Through our website, you can easily access 3D interior and exterior design services tailored to your specific needs. With our help, you'll be able to create stunning visual representations of your designs, allowing you to present them to clients, investors, or stakeholders in a professional and engaging manner. Our team focuses on bringing out the best in your designs, ensuring that both the interior spaces and exterior elements are rendered with the highest level of detail and realism.