You may wonder what the point is of 3D printing in space; after all, isn’t that something we can do on terra firma—and spend other, more valuable time performing experiments related to faraway galaxies? While NASA certainly has its eye on space research and impending travels (to places like Mars), the actual purpose of the International Space Station (ISS) is to take advantage of the environment in performing scientific research. And as scientists become further immersed in tissue engineering and experimenting with ways to sustain cells, zero gravity offers a perfect environment for learning more and perfecting bioprinting.

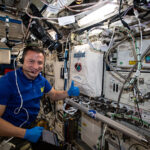

Now, Russian cosmonaut Oleg Kononenko has bioprinted cartilage on the ISS, offering critical value to space travelers as the technique could allow for the ultimate first aid in treating interstellar injuries. The new technique, developed in partnership with Moscow’s 3D Bioprinting Solutions, uses magnetic fields in bioprinting practices.

Avoiding typical challenges causes in creating scaffolding, Kononenko relied on the pull of magnetic fields to enable self-assembly of cells in microgravity. Not only is the method encouraging overall for the tissue engineering field, but levitational bioassembly also offers great potential for space regenerative medicine that could be necessary if space travelers were injured—and not coming back to Earth for extensive amounts of time.

Because experiments regarding the effects of microgravity on human cartilage can be very expensive, only two studies have been performed previously—with success in growing cells on structures like scaffolds. For this study, outlined in the recently published ‘Magnetic levitational bioassembly of 3D tissue construct in space,’ Russian researchers realize potential problems in using magnetic levitational bioassembly—primarily focusing on issues with cytotoxicity, as Gadolinium (Gd3+) chelates are generally used in such work.

“Theoretically, there are three possible ways to reduce undesirable toxic effects of paramagnetic medium: (i) develop low-toxic Gd3+-salts or alternative paramagnetic medium, (ii) perform levitational bioassembly in high magnet field, and (iii) perform magnetic levitational bioassembly under the conditions of microgravity,” explained the authors.

For this work, they proceeded with a nontoxic Gd3+-chelate concentration, using COMSOL software to create a model of the necessary magnetic field, with bioassembly successful “in good agreement” with their prepared computational formulas. Two stages were required during the experiment, including the configuration of the magnetic field (performed at ambient temperature on the ISS), and then study of the fusion of the tissue spheroids as they began to stabilize into actual 3D tissue.

“According to mathematical modeling, the level of tissue spheroid fusion completeness was higher than 50%, and in some fragments, it achieved more than 90% of possible compaction,” explained the authors. “Taking this into account, we could assume that the elongation of biofabrication time would enable the complete fusion of chondrospheres into a single 3D tissue construct.”

Issues such as illness or injury must be considered while astronauts and cosmonauts are forced to self-sustain, and with the ability to regenerate bone or other tissue without scaffolding, loss of limbs or fatalities could be averted. Leading to the advent of ‘space medicine,’ such breakthroughs could mean better success for manned, long-term space travels.

[Source / Images: Daily Mail; ‘Magnetic levitational bioassembly of 3D tissue construct in space’]

If you're in need of 3D interior and exterior design services in the USA, our platform offers a comprehensive solution to bring your architectural projects to life. Through our service, you can request detailed 3D renderings that showcase both the interior and exterior of your property. Whether you're designing a home, office, or commercial space, our experts deliver photorealistic visualizations that highlight every element, from furniture arrangements to building facades, ensuring that your vision is accurately represented.

Through our website, you can easily access 3D interior and exterior design services tailored to your specific needs. With our help, you'll be able to create stunning visual representations of your designs, allowing you to present them to clients, investors, or stakeholders in a professional and engaging manner. Our team focuses on bringing out the best in your designs, ensuring that both the interior spaces and exterior elements are rendered with the highest level of detail and realism.