Researchers continue to experiment with materials and extrusion techniques, introducing the use of chaotic flows for improved microarchitectures in the recent study, ‘‘Using chaotic advection for facile high-throughput fabrication of ordered multilayer micro- and nanostructures: continuous chaotic printing.’

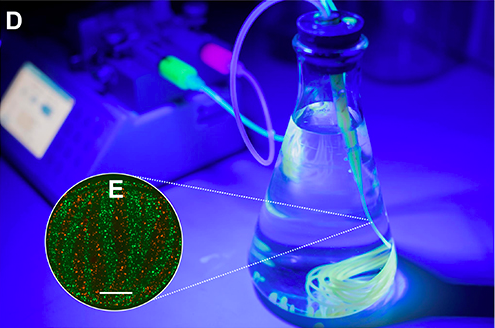

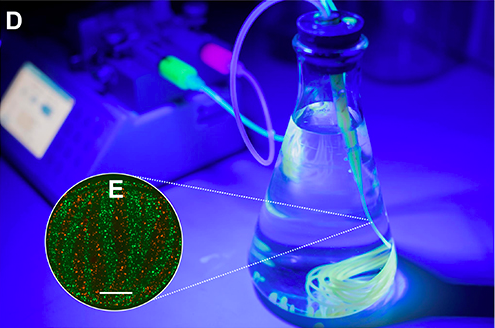

The authors present a unique form of fabrication with a method that allows for more precise control of the structure and surface area being printed through the use of what they call ‘continuous chaotic printing.’ The process relies on a combination of chaos theory and fluid dynamics, in which the flow of material develops into complex fractals. To achieve this, the team created chaotic material flows by reorienting and splitting fluid as it is mixed, as shown in the figure below.

With a focus on multiple materials, multiple layers, and fabrication of varying cells in proximity to each other on larger surfaces, their goal was to test the potential for chaotic printing in a variety of applications, but with a special focus on bioprinting and biomedical research. Building on previous research with chaotic flow, the authors experimented with a chaotic printer (paired with a Kenics static mixer), fabricating fibers made from alginate.

An unlimited number of inks can be used in chaotic printing, but for this study, the researchers used basic techniques, with sodium alginate as a base. Experiments were then performed with composite inks featuring suspensions like polymer microparticles, graphite microparticles, mammalian cells, or bacteria. Ultimately, the team reported they were able to print ‘fine and well-aligned microstructures’ at high extrusion speeds of 1–5 m of fiber/min.

“This printing strategy is also robust across a wide range of operation settings. We conducted a series of printing experiments at different inlet flow rates to assess the stability of the printing process. As long as the flow regime is laminar and the fluid behaves in a Newtonian manner, the quality of the printing process is not affected by the flow rate used in a wide range of flow conditions,” explained the authors.

The researchers also noted the following while printing:

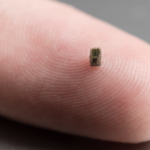

- Stable fibers were printed using a cone-shaped nozzle tip with an outlet diameter of 1 mm, with flow rates ranging from 0.003 to 5.0 ml min−1.

- Printheads with varying geometries did not affect structures being printed.

- Computational fluid dynamics (CFD) showed that the inclination of the nozzle tip also did not affect the materials.

Continuing to emphasize the ‘robust’ qualities of chaotic printing—especially when used with small nozzles—the researchers were able to control resolution, noting also that, due to the deterministic qualities of chaotic flows, fabrication of structures was ‘fully predictable.’ Resolution was in part illustrated by the number of gill-like ridges, or ‘lamellae,’ created through the chaotic mixing process.

“As the number of elements used to print increased, the number of lamellae observed in any given cross-sectional plane of the fiber also increased, while the thickness of each lamella decreased,” explained the researchers. “Therefore, users of continuous chaotic printing will have more degrees of freedom to determine the multi-scale resolution of a construct, as this is no longer mainly restricted by the diameter of the nozzle (or the smallest length-scale of the nozzle at cross-section).”

Further, as the researchers began experimenting with bioprinting, they were able to create alginate fibers rich with cells, and lightly enriched with protein to encourage ongoing sustainability. This is one of the greatest challenges in tissue engineering. Even though the correct materials, techniques, and concepts may be in place, if researchers cannot keep the cells alive long enough, they must go back to the drawing board.

Altogether, the team suggests that it has developed a completely novel way to control the resolution of an extrusion-based printing system. As shown in the image below, not only can this continuous chaotic printing process control print resolution through the diameter of the nozzle, but at the microscale as well through the chaotic mixing techniques deployed.

The researchers noted that not only could this have a profound impact on multimaterial printing technologies, but on bioprinting as well:

“Our results demonstrate the unrivaled ability of chaotic printing to deploy cells within high SAV fibers. As available bioprinting and bioassembly technologies approach the resolution and SAV of chaotic printing, they also tend to require long fabrication times and mechatronically coordinated control systems,” concluded the researchers. “In addition to multicellular, high SAV constructs, chaotic printing offers other breakthroughs in regards to currently available multimaterial printing technologies that, typically, require optimized inks that must be deployed under a specific and narrow range of conditions.”

[Source / Images: ‘Using chaotic advection for facile high-throughput fabrication of ordered multilayer micro- and nanostructures: continuous chaotic printing’]

If you're in need of 3D interior and exterior design services in the USA, our platform offers a comprehensive solution to bring your architectural projects to life. Through our service, you can request detailed 3D renderings that showcase both the interior and exterior of your property. Whether you're designing a home, office, or commercial space, our experts deliver photorealistic visualizations that highlight every element, from furniture arrangements to building facades, ensuring that your vision is accurately represented.

Through our website, you can easily access 3D interior and exterior design services tailored to your specific needs. With our help, you'll be able to create stunning visual representations of your designs, allowing you to present them to clients, investors, or stakeholders in a professional and engaging manner. Our team focuses on bringing out the best in your designs, ensuring that both the interior spaces and exterior elements are rendered with the highest level of detail and realism.