Polish 3D printing solutions provider Zortrax has been working with the European Space Agency (ESA) for the last year to figure out how to use 3D printing to fabricate high-performance composite parts out of two different PEEK (polyetheretherketone) filament blends, and the two have finally reached a milestone in the project.

At the recent FabAddComp scientific conference in France, the ESA revealed during the keynote that the industrial Zortrax Endureal printer, which features dual extruders, is able to print models using two space-grade PEEK polymers, and so can support 3D printing components with built-in electronics and electrical circuits.

The Zortrax Endureal is a third generation industrial LPD Plus 3D printer, with a 400 x 300 x 300 mm build space, and featuring over 30 built-in sensors that work in real-time to guarantee uninterrupted operation in high-tech manufacturing and product development projects. Often used to fabricate components out of high-performance polymers like Z-PEI 9085 and PEEK-based materials already, the Endureal’s dual extrusion technology is typically used to print a model and its support structures out of two different materials. But, the aerospace sector is seeing a higher demand for 3D printed composite parts featuring two high-performance polymers, which is what the ESA and Zortrax have just done.

NASA has used Zortrax systems in the past to make tools, so the company’s printers are clearly able to handle aerospace applications already. But now, the ESA has developed an experimental, electrically conductive PEEK material blend, which Zortrax used, together with pure PEEK, to create 3D printed proof of concept composite models, featuring simple electricity, on its Zotrax Endureal.

“Reducing weight is always one of the key design goals in aerospace engineering and it can be done by building parts which serve multiple purposes at once,” explained Michał Siemaszko, Head of Research and Development at Zortrax S.A. “In a standard airplane or spacecraft, you need to include both structural elements and wiring responsible for transferring energy or data between various systems. That is what we aim to solve with 3D printing PEEK components with electrically conductive paths. This way, the structural parts can at the same time perform electricity or data transfer functions without weight penalty incurred for additional wires. Imagine casting a solid steel slab that also works as a USB connector. That’s what the Endureal can do with high- performance polymers.”

Together with the ESA, Zortrax has successfully 3D printed what it’s calling “the world’s first data transfer device” entirely out of PEEK polymers.

“A data transfer of 9600 bit/s has been achieved between two computers connected with USB cables and USB-RS232 converters through a 3D printed model,” the company stated on its website. “We have also fabricated models with built-in electrically conductive paths.”

The Zortrax Endureal system is divided into three separate thermally isolated zones: the print chamber, the filament compartment, and the extruder compartment. It was an impressive printer already, with automated annealing and advanced filament sensors, but for the ESA project, the company’s engineering team worked to make it even better. In addition to updating the software and firmware, the industrial printer can now achieve better dimensional accuracy thanks to increased rigidity of the extrusion system, and additional tweaks to the hardware have enabled the Endureal to reach even higher operating temperatures; for instance, the maximum extrusion temperature is now 480°C. Users can now precisely define the temperature in the print chamber, which can now reach 200°C, and the PEI film-covered aluminum built platform can get up to 220°C, which helps decrease material shrinkage and warping.

“The technology we are developing opens up a clear path to use the Zortrax Endureal for 3D printing smart components with built-in electrical circuits, all while retaining excellent thermal and mechanical properties of high-performance polymers like PEEK,” stated Zortrax CEO Rafał Tomasiak. “This will make this printer a powerful tool in the hands of engineers and designers working for high end and demanding application like automotive, aerospace and space. We also expect groundbreaking solutions developed in projects like this one to quickly trickle down to our production level 3D printers.”

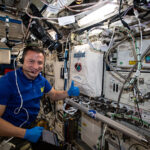

As a bonus for other customers, Zortrax has implemented all of the changes and improvements in the design of the Endureal to all commercially available systems, in order to ensure dual extrusion 3D printing of composite models with pure and conductive PEEK. What this also means is that the technology could eventually make it into space one day, expanding the possibilities of what can be manufactured aboard the ISS or even on potential bases on the Moon.

(Source/Images: Zortrax)

If you're in need of 3D interior and exterior design services in the USA, our platform offers a comprehensive solution to bring your architectural projects to life. Through our service, you can request detailed 3D renderings that showcase both the interior and exterior of your property. Whether you're designing a home, office, or commercial space, our experts deliver photorealistic visualizations that highlight every element, from furniture arrangements to building facades, ensuring that your vision is accurately represented.

Through our website, you can easily access 3D interior and exterior design services tailored to your specific needs. With our help, you'll be able to create stunning visual representations of your designs, allowing you to present them to clients, investors, or stakeholders in a professional and engaging manner. Our team focuses on bringing out the best in your designs, ensuring that both the interior spaces and exterior elements are rendered with the highest level of detail and realism.