Researchers Zi Wang and Stephen J. Florczyk of the University of Central Florida have developed a new technique for bioprinting, outlined in the recently published ‘Freeze-FRESH: A 3D Printing Technique to Produce Biomaterial Scaffolds with Hierarchical Porosity.’

Although many researchers and laboratories are engaged in bioprinting today, and reporting success, great challenges still remain for improving viability and sustainability of cells in tissue engineering. While bioprinting is a field that is still relatively new—and full of incredible potential for the end-game in 3D printing human organs—methods and materials abound; however, in this study, a truly unique new way of 3D printing emerges to overcome obstacles in production of single conventional scaffolds. The Freeze-FRESH (FF) technique integrates freeze casting with 3D printing, resulting in scaffolds that bear microscale pores in the struts.

FRESH, freeform reversible embedding of suspended hydrogels, employs gelatin in the support bath—where scaffolds (printed at room temperature) are frozen in the support bath, leaving researchers to study:

- Pore morphology

- Pore size

- Porosity

- Shrinkage

- Stiffness

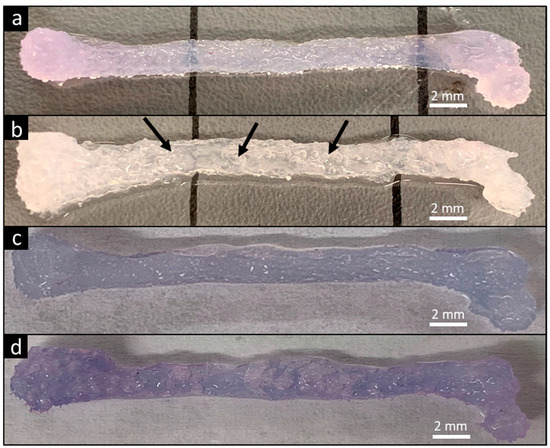

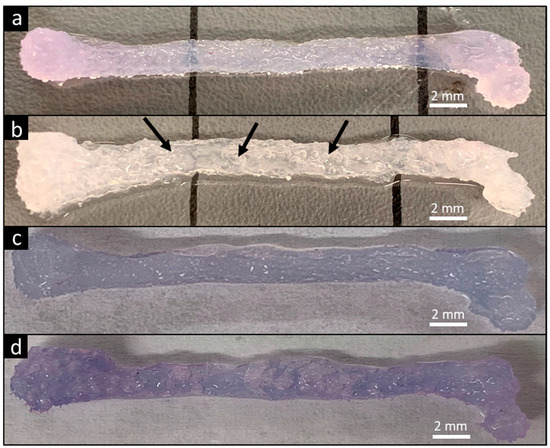

“The FF scaffolds had a hierarchical pore structure from the combination of microscale pores throughout the scaffold struts and macroscale pores in the printed design, while control scaffolds had only macroscale pores,” explained the researchers.

Temperature parameters resulted in the following:

- FF scaffolds frozen at −20 °C and −80 °C had similar pore sizes.

- The −20 °C and −80 °C FF scaffolds had porous struts with 63.55% ± 2.59% and 56.72% ± 13.17% strut porosity.

- Control scaffolds had a strut porosity of 3.15% ± 2.20%.

- The −20 °C and −80 °C FF scaffolds were softer than control scaffolds.

Clusters of cells grew on the porous struts, leading to good microscale porosity in the 3D printed scaffolds, ‘enhancing MDA-MB-231 growth’ for culturing breast cancer cells. The researchers created samples (measuring 20 mm × 20 mm × 6 mm) designed in SolidWorks and fabricated using a Biobots 1 3D printer. A sample model of a human femur was also printed via the FF method, measuring 44.96 mm × 7.95 mm × 6.91 mm (l × w × h), and treated the same way as the scaffolds.

Overall, the samples showed good structure, and stability after being soaked. The smooth scaffold samples did not present bubbles, although FF scaffolds did, which were noted as ‘indicating pore formation’ in the struts.

Smooth scaffolding showed the greatest bulk stiffness, ahead of the −20 °C and −80 °C FF scaffolds, and then the FC scaffolds, showing the least amount of bulk stiffness. The researchers noted ‘significant differences’ in all paired groups except the −20 °C and −80 °C FF scaffolds.

“Both smooth and FF scaffolds remained intact without damage after bending. When bent further, the smooth scaffolds started to delaminate and lose structural integrity. The reduced cross-sectional area in the FF scaffolds may enable this greater resilience,” explained the researchers.

“The 231 cells formed multicellular clusters on struts of FF scaffolds and had similar morphologies to the cells cultured in the FC scaffolds. Our work demonstrated that FF printing produced scaffolds with hierarchical pore structures that improved breast cancer cell growth. In future studies, other polymer inks will be evaluated for FF printing to broaden the materials that can be used.”

What do you think of this news? Let us know your thoughts! Join the discussion of this and other 3D printing topics at 3DPrintBoard.com.

[Source / Images: ‘Freeze-FRESH: A 3D Printing Technique to Produce Biomaterial Scaffolds with Hierarchical Porosity’]

If you're in need of 3D interior and exterior design services in the USA, our platform offers a comprehensive solution to bring your architectural projects to life. Through our service, you can request detailed 3D renderings that showcase both the interior and exterior of your property. Whether you're designing a home, office, or commercial space, our experts deliver photorealistic visualizations that highlight every element, from furniture arrangements to building facades, ensuring that your vision is accurately represented.

Through our website, you can easily access 3D interior and exterior design services tailored to your specific needs. With our help, you'll be able to create stunning visual representations of your designs, allowing you to present them to clients, investors, or stakeholders in a professional and engaging manner. Our team focuses on bringing out the best in your designs, ensuring that both the interior spaces and exterior elements are rendered with the highest level of detail and realism.