In ‘Towards Digital Manufacturing of Smart Multimaterial Fibers,’ Indiana researchers explore the use of fibers in 3D printing, along with the potential for expanding their functionality into smart materials that also encompass high-performance electronics. Super-efficient fibers are used in various applications today, including high-speed telecommunications and global data storage—and optics such as fiber optic sensors (FOS) are used in serious applications like biomedical, oil and gas, aerospace, and more.

In comparison to more conventional fiber materials, smart fibers can be used in applications like commercial fabrics. To make them functional, the following is required:

- Conductivity

- Specially designed architecture

- Features reduced to the nanoscale

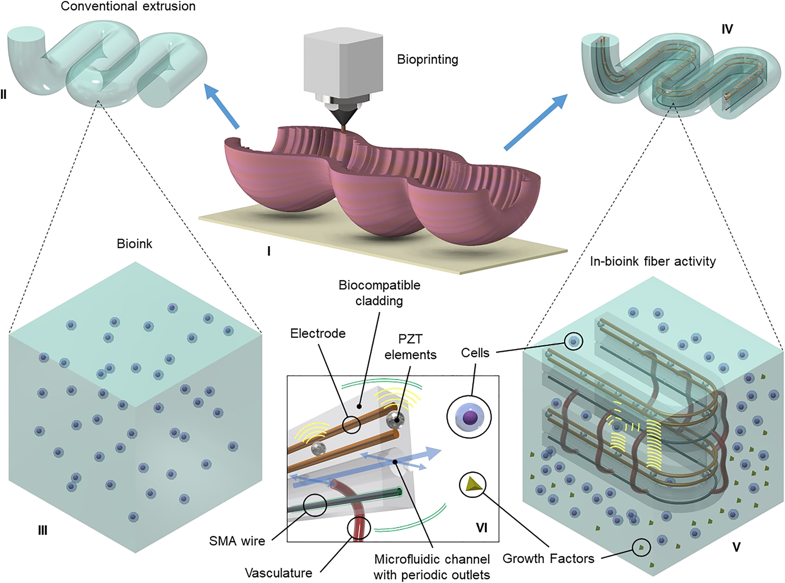

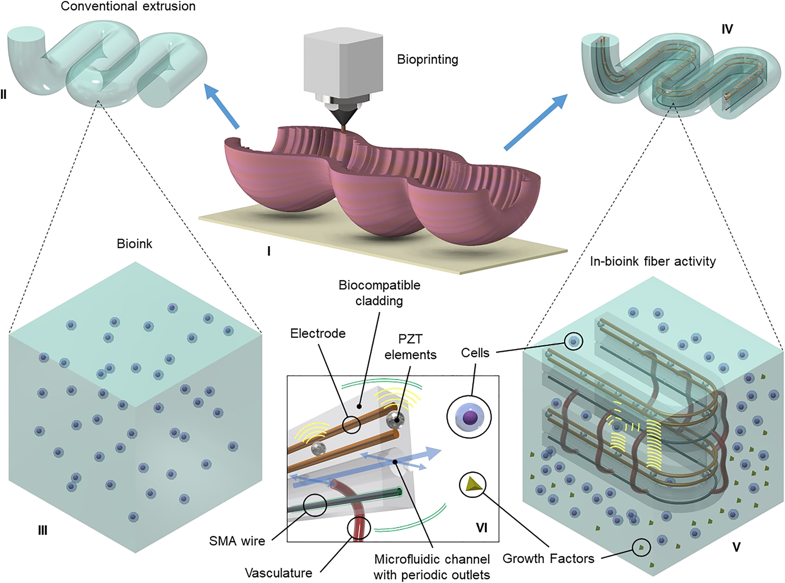

A preform is built, and while there are several ways to do so, 3D printing is one possible technology. Fibers can also be woven into different structures for added strength and used as synthesis platforms for the production of materials, as well as sensors. The benefits of 3D printing can be enjoyed too, made easily accessible, affordable, and user-friendly in many cases. The authors state that 3D printing is also attractive for fabrication due to feasibility with so many different types of materials, to include thermoplastics, biomaterials, and more.

In using the concept of very large-scale integration (VLSI) for fibers (VLSI-Fi), the researchers can combine liquid phase processing techniques to create a ‘toolbox’ for fabricating a range of devices and systems. Here, the team focuses on ‘narrower aspects’ of VLSI-Fi and the following:

- Preform 3D printing

- In-fiber circuit assembly

- Segregation-driven doping control

“In addition, the FAMES Lab has the ability to process high-temperature materials, alongside the more traditional use of thermoplastics in additive manufacturing, allowing us to take advantage of properties such as the high electron mobility in Si/Ge, as well as the future use of lead zirconate titanate (PZT)/BaTiO3 composites for piezoelectric applications having large piezoelectric coefficients compared to polymers and higher acoustic bandwidth,” stated the researchers.

Fibers are often used in the biomedical realm, for applications related to medical, physical, and chemical sensors that could monitor stress, temperature, moisture, and other settings.

“Examples of smart fiber development include a neural fiber probe composed of a polymer and metal core composition that enables flexibility and bending stiffness of the neural probe as it provides in vivo optogenetic stimulation and delivers drugs as an input in order to record feedback electrical and physiological output signals,” state the researchers.

“Another example is a fiber integrating microfluidic principles with complex cross-sectional geometries and meter-long microchannels which analyzes cell separation by dielectrophoresis (DEP). Live and dead cells are separated by inertial and dielectrophoretic forces by sheathless, high-throughput microfluidic cell separator which contains conductive materials in the microchannels.”

Biosensors can also be created in a multitude of different ways and can monitor cells, bacteria, DNA, and more. Ultimately, the researchers see VLSI-Fi as allowing for the realization of product in numerous areas of technology, beginning with active biomimetic scaffolds.

“We believe that this method will deliver a new class of durable, low cost, pervasive fiber devices, and sensors, enabling integration of fabrics met with human-made objects, such as furniture and apparel, into the Internet of Things (IoT). Furthermore, it will boost innovation in 3D printing, extending the digital manufacturing approach into the nanoelectronics realm,” conclude the authors.

3D printing has opened up a wide expanse of materials science, to include innovation with fibers and sensors for wearables, fiber optics, and biomedical applications. What do you think of this news? Let us know your thoughts! Join the discussion of this and other 3D printing topics at 3DPrintBoard.com.

[Source / Images: ‘Towards Digital Manufacturing of Smart Multimaterial Fibers’]

If you're in need of 3D interior and exterior design services in the USA, our platform offers a comprehensive solution to bring your architectural projects to life. Through our service, you can request detailed 3D renderings that showcase both the interior and exterior of your property. Whether you're designing a home, office, or commercial space, our experts deliver photorealistic visualizations that highlight every element, from furniture arrangements to building facades, ensuring that your vision is accurately represented.

Through our website, you can easily access 3D interior and exterior design services tailored to your specific needs. With our help, you'll be able to create stunning visual representations of your designs, allowing you to present them to clients, investors, or stakeholders in a professional and engaging manner. Our team focuses on bringing out the best in your designs, ensuring that both the interior spaces and exterior elements are rendered with the highest level of detail and realism.